DO0167

For Sale From Direct Owners

| Reference | DO0167 |

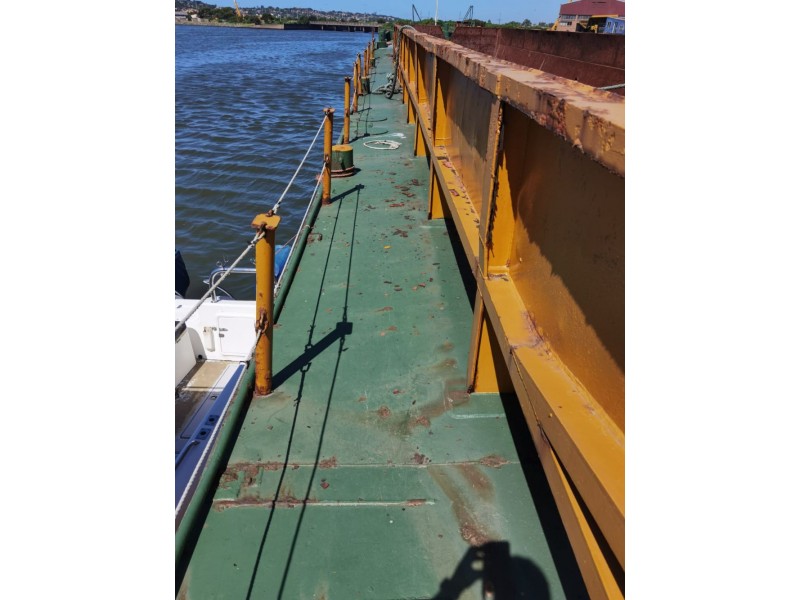

| Type | Barge - Split Barge |

| Class | local class |

| Build year / place | 1979 / HUNGARY |

| Length (m) | 44 |

| Breadth (m) / Depth (m) | 7.95 / 2.8 |

| NT (tons) / GT (tons) | / 178 |

| Engine(s) power (BHP) | 700 |

| Engine(s) | 2 x Caterpillar |

| Location | SOUTH AFRICA |

| Price | 375,000 USD |

Interested in this vessel?

Please, feel free to contact us at any time.

We remain at your entire disposal.

Detailed Information

General

| Built Year & Place | 1979 / HUNGARY |

| Hull Material | steel |

| Flag | SOUTH AFRICA |

| Class Society and Notation | local class Cargo Barge |

| Next DD | |

| Next SS | |

| Next Annual Survey |

Principle Dimensions

| Length Overall (m) | 44 |

| Length Between Prep. (m) | 43.3 |

| Breadth (m) | 7.95 |

| Depth (m) | 2.8 |

| Draft (m) | |

| NT (tons) | |

| GT (tons) | 178 |

| DWT (tons) |

Machinery & Propulsion

| Total Power Output (BHP) | 700 |

| Main Engine(s) | 2 x Caterpillar |

| Main Propulsion System | Schottel |

| Auxiliary engine(s) | |

| Propellers | |

| Speed Maximum (knots) | |

| Speed Cruising (knots) |

Cargo & Tank Capacities

| Deck Cargo (tons) | |

| Deck Area (m2) | |

| Deck Load (tons/m2) | |

| Fuel Tanks Capacity (m3) | |

| Fresh Water Tanks Capacity (m3) | |

| Ballast Tanks Capacity (m3) |

Additional Information

Vessel is currently in laid up condition with certificates expired.

They can remove the power packs and impellers from the barge.

The split cylinder and engine will still remain as part of the split hopper barge but it will then be non self propelled. Price would be decreased to 340,000 USD.

Year of Refit : 2010

Hopper Capacity : 260 m3

Breadth extreme: 7.99 m

Average shell thickness: 8mm

Engine serves as a 400 litre diesel fuel tank

Integrated hydraulic power pack directly coupled to the diesel engine through an elastic coupling

Hydraulic driven, cowled rudder propeller (4 blades x 950 mm dia), mounted on a sliding lifting frame, steerable using hydraulic cylinders. The lifting frame allows vertical movement of the propeller unit by 1000 mm. A shear pin allows the unit to til upwards by 400 in the event of impact while travelling in the fwd direction.

Steel control cabin in aft, mounted on a base frame with pivot/wheel assembly to retain the cabin in a horizontal position as the split hopper is opened.

The cabin houses the propulsion unit control console, the control panel for the hydralic hopper opening cylinders as well as communication and navigation equipment and basic crew facilities.

The control console for the engines provides separate functions for each propulsion unit, controlling:

– Diesel engine start, speed and emergency stop

– Propeller speed

– Propelor direction of rotation

– Steering angle (+65 to -65)

– Propeller lift

– Emergency stop

– Alarms units with buzzer, test and alarm release functions for: Low hydraulic oil level, Low boost pressure and High temperature/overheating

This split hopper barge has been fitted out as a self-propelled barge for the transporting of small volumes of dredge materials. It can cater for soft and rock materials, with a capacity of 350t when full. The hopper is also equipped with marine radios and a disposal tracking system.

All details are given in good faith and are believed to be accurate but no warranty of accuracy or completeness or suitability for purpose is either stated or implied. Prices are subject to change without notice.